-

Glass Machinery Parts

-

Kevlar Aramid Ropes

-

Kevlar Sleeves Tube

-

Solid State Relay

-

Universal Caster

-

Heating Elements

-

Fused Silica Roller

-

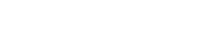

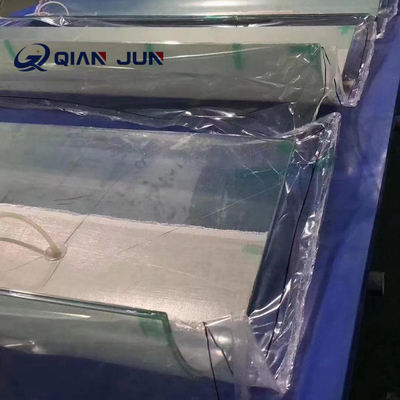

Vacuum Bagging Film

-

Insulating glass machine accessories

-

Abrasive Tools

-

CNC Glass Cutting Machine

-

Glass Edging Machine

-

Glass Washing & Drying machine

-

Glass Tempering Machinery Accessories

-

Consumable Material

-

Transmission Belts

Laminated glass use Clear Heat Vacuum Film for laminating- 90micrometer Thickness

| Packaging | Roll | Heat Resistance | 160°C-180°C |

|---|---|---|---|

| Surface | Smooth | Moisture Barrier | Excellent |

| Puncture Resistance | Excellent | Width | 1650mm, 2100mm, 2300mm, 2500mm, 3000mm |

| Thickness | 90micrometer | Color | Clear |

| Film width | Film length | Temperature resistance | |

|---|---|---|---|

| 1650mm | 250meters | 160°C | |

| 2100mm | 250meters | 160°C | |

| 2300mm | 250meters | 160°C | |

| 2500mm | 250meters | 160°C | |

| 2700mm | 250meters | 160°C | |

| 3000mm | 250meters | 160°C |

Laminated glass use Clear Heat Vacuum Film for laminating- 90micrometer Thickness

Product Description:

Vacuum Bagging Film for Laminated glass use helps ensure high quality production.

This high temperature resistant nylon vacuum bag film has a temperature resistance range from 160-180℃, superior tensile strength, and is tailored for composite material hot-press molding process. High temperature and high pressure conditions won't affect its great barrier properties, making it an ideal choice for a variety of resin system vacuum bag technology.

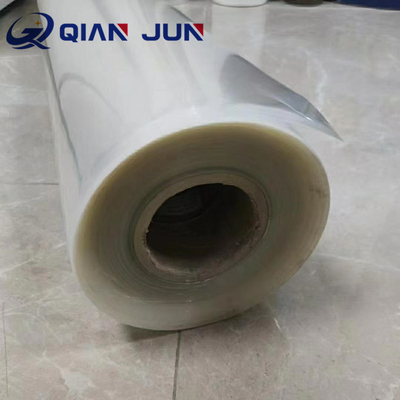

This film is essential for producing curved tempered glass, hot-bending glass laminating, DuPont SGP glass laminating which is more difficult to roll process due to the arc length or high arch height.

In the traditional production process, formers need to seal the glass with a vacuum strip around the circle and put in the drying box. However, this method has the problem of incomplete seal and high equipment cost, resulting in lowyield.

Vacuum Baggin film for Laminated glass use helps solve this problem. It simplifies the process by completely sealing the glass in a vacuum bag and directly entering the autoclave to vacuum and form. This method give high yields, high efficiency and easy to learn, and can be used to make super large and wide laminated glass.

Features:

- Product Name: Vacuum Bagging Film

- Thickness: 90 micrometer

- Oxygen Barrier: Excellent

- Material: Polyethylene & Nylon

- Packaging: Roll

- Width: 1650mm, 2100mm, 2300mm, 2500mm, 3000mm

- Ideal for Vacuum Sealing and Vacuum Wrapping

- High Quality Vacuum Sealing Film Roll

Technical Parameters:

| Parameter | Value |

|---|---|

| Product Name | Vacuum Bagging Film |

| Puncture Resistance | Excellent |

| Moisture Barrier | Excellent |

| Surface | Smooth |

| Thickness | 90micrometer |

| Heat Resistance | 160°F |

| Width | 1650mm, 2100mm, 2300mm, 2500mm, 3000mm |

| Tear Resistance | Excellent |

| Packaging | Roll |

| Recyclable | No |

| Oxygen Barrier | Excellent |

| Type | Thermal Sealing Film, Thermal Shrinkable Film, Thermal Shrinkable Film, Vacuum Bagging Film |

Applications:

Vacuum bagging film is mainly used for processing laminated glass, and is capable of dealing with a wide variety of products, even the difficult ones (e.g. curved or embossed glass, and DuPont SGP explosion-proof film laminated ones). With its high yield and easy-to-learn features, the users are spared from a huge investment (the cost is much lower than that of similar foreign products). At present, our technology has been adopted by a number of prominent glass processing companies like CSG, AVIC Sanxin, Chuangyi Technology, Jiangmen Junfa Glass, Foshan Nanliang, Jiangsu Aolan, etc.

Support and Services:

Technical support and service for Vacuum Bagging Film are available to ensure customer satisfaction. Our team of experienced professionals are available to provide product information, troubleshooting advice and technical guidance for the installation, operation and maintenance of Vacuum Bagging Film. We also offer a variety of custom services, such as product design and development, to meet special customer needs. Our team is committed to providing timely and reliable solutions that meet our customers' needs.

Packing and Shipping:

Vacuum Bagging Film packaging and shipping is done in the following steps:

- The film is folded neatly and placed in a cardboard box or similar container.

- The box is securely sealed.

- The box is labeled with the recipient's name and address.

- The box is placed in a larger box or onto a pallet.

- The larger box or pallet is labeled with the recipient's name and address.

- The box or pallet is shipped to the recipient via a reputable carrier.

![]()