-

Glass Machinery Parts

-

Kevlar Aramid Ropes

-

Kevlar Sleeves Tube

-

Solid State Relay

-

Universal Caster

-

Heating Elements

-

Fused Silica Roller

-

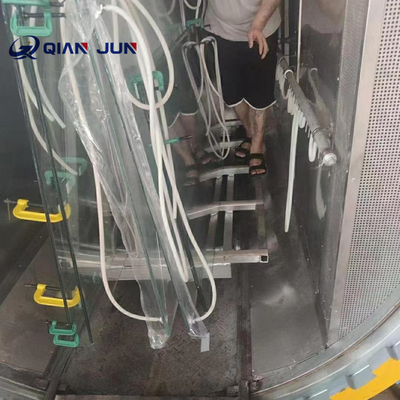

Vacuum Bagging Film

-

Insulating glass machine accessories

-

Abrasive Tools

-

CNC Glass Cutting Machine

-

Glass Edging Machine

-

Glass Washing & Drying machine

-

Glass Tempering Machinery Accessories

-

Consumable Material

-

Transmission Belts

Polyethylene Nylon Vacuum Bagging Film - Excellent Heat resistance Tear Resistance for sealing

| Material | Polyethylene & Nylon | Tear Resistance | Excellent |

|---|---|---|---|

| Puncture Resistance | Excellent | Packaging | Roll |

| Heat Resistance | 160°C | Length | 250METERS |

| Oxygen Barrier | Excellent | Surface | Smooth |

Product Description:

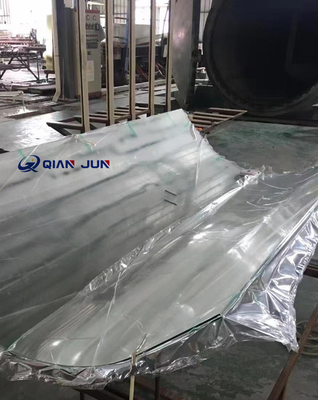

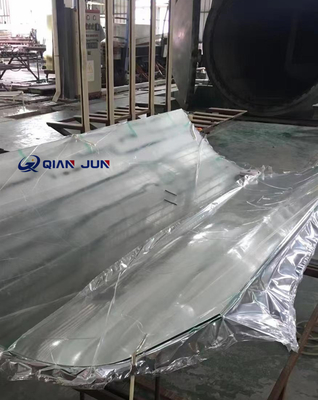

Vacuum Bagging Film is specially designed for the composite material hot-press molding process that needs a high temperature resistance range from 160-180℃, it has high tensile strength and a good barrier properties under high temperature and high pressure. It is suitable for a variety of resin system vacuum bag technology, especially for making laminated glass

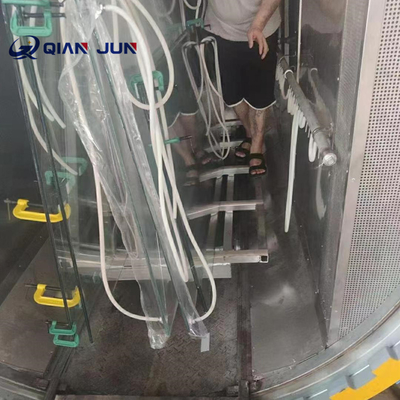

When laminating the DuPont SGP explosion-proof film, the traditional method is to put the glass with a vacuum strip surround it into the drying box and vacuum it, then enter the autoclave. This method often causes product quality problem, the input of the drying box and process is increasing, as well as the cost and the efficiency is low. Also this method is not applicable for the patterned glass with wavy surface because the vacuum strip cannot seal the glass.

While our solution is to completely seal the glass with a vacuum bag and directly into the autoclave for vacuuming and form once. It has characteristic of high yield, high efficiency and easy to learn. It also applicable for making super large and wide laminated glass.

Features:

- Product Name: Vacuum Bagging Film

- Puncture Resistance: Excellent

- Color: Clear

- Oxygen Barrier: Excellent

- Thickness: 90micrometer

- Recyclable: No

- Features: Vacuum Sealing Film, Thermal Shrinkable Film, Vacuum Wrapping Film

Technical Parameters:

| Parameter | Value |

|---|---|

| Length | 250METERS |

| Tear Resistance | Excellent |

| Thickness | 90micrometer |

| Width | 1650mm, 2100mm, 2300mm, 2500mm, 3000mm |

| Oxygen Barrier | Excellent |

| Heat Resistance | 160°F |

| Moisture Barrier | Excellent |

| Surface | Smooth |

| Recyclable | No |

| Color | Clear |

| Type | Heat Shrinkable Film, Heat Sealing Film, Vacuum Wrapping Film |

Applications:

Vacuum bagging film is mainly used for processing laminated glass, which can process a variety of difficult laminated glass products. For example, it can process a variety of curved glass or embossed glass laminates, as well as United States DuPont SGP explosion-proof film laminating. Moreover, our technology has high yield and it is easy to learn, with less investment (the price is significantly lower than that of similar foreign products). Currently, CSG, AVIC Sanxin, Chuangyi Technology, Jiangmen Junfa Glass, Foshan Nanliang, Jiangsu Aolan and many other companies all utilize our technology.

Support and Services:

Our technical support and services for Vacuum Bagging Film include:

- 24/7 online technical support for customers using Vacuum Bagging Film

- On-site installation and setup services

- Troubleshooting and repair services

- Frequent software and firmware updates

- Consultancy and advisory services

Packing and Shipping:

Vacuum Bagging Film is packaged and shipped in rolls, in sealed plastic bags. The bags are marked with the product name, the size of the film, and a description of the product. The bags are securely sealed and placed in sturdy cardboard boxes. The boxes are then labeled with the product name and other relevant information. The boxes are then securely sealed and shipped according to the customer's specifications.![]()