-

Glass Machinery Parts

-

Kevlar Aramid Ropes

-

Kevlar Sleeves Tube

-

Solid State Relay

-

Universal Caster

-

Heating Elements

-

Fused Silica Roller

-

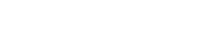

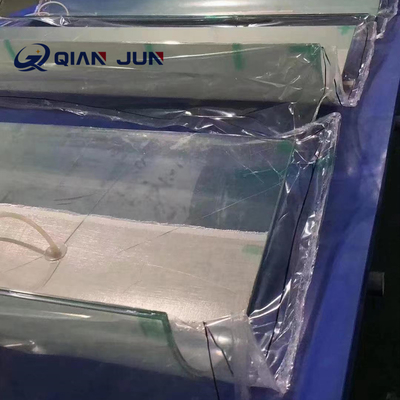

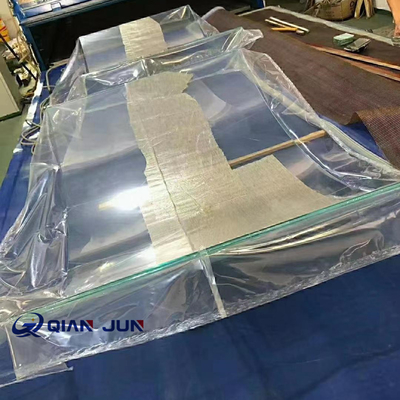

Vacuum Bagging Film

-

Insulating glass machine accessories

-

Abrasive Tools

-

CNC Glass Cutting Machine

-

Glass Edging Machine

-

Glass Washing & Drying machine

-

Glass Tempering Machinery Accessories

-

Consumable Material

-

Transmission Belts

Nylon Heat Sealing Film Vacuum bagging film laminated glass Protective Roll Packaging Solution Polyethylene

| Color | Clear | Tear Resistance | Excellent |

|---|---|---|---|

| Puncture Resistance | Excellent | Length | 250METERS |

| Heat Resistance | 160°C | Material | Polyethylene & Nylon |

| Width | 1650mm, 2100mm, 2300mm, 2500mm, 3000mm | Thickness | 90micrometer |

Nylon Heat Sealing Film Vacuum bagging film laminated glass Protective Roll Packaging Solution Polyethylene

Product Description:

High temperature resistant nylon vacuum bag film, with a temperature resistance range from 160-180℃, high tensile strength, specially designed for the composite material hot-press molding process, good barrier properties under high temperature and high pressure, suitable for a variety of resin system vacuum bag technology.

Vacuum Bagging film for making laminated glass is mostly used when processing curved tempered glass or hot-bending glass laminating, due to the arc length or high arch height of the glass. And when laminating the DuPont SGP explosion-proof film, the vacuum belt usually only surrounds the glass one circle which is not completely sealed, resulting in product quality problem, increased equipment and process input of the drying box as well as higher cost and lower efficiency.

However, our solution is to completely seal the glass with a vacuum bag and directly into the autoclave for vacuuming and forming once. It has the characteristics of high yield, high efficiency and easy to learn. This method is also suitable for making super large and wide laminated glass.

Features:

- Product Name: Vacuum Bagging Film

- Material: Polyethylene & Nylon

- Packaging: Roll

- Surface: Smooth

- Color: Clear

- Length: 250METERS

- Features: Thermal Shrinkable Film, Thermal Shrinkable Film, Vacuum Wrapping Film

Technical Parameters:

| Property | Value |

|---|---|

| Puncture Resistance | Excellent |

| Tear Resistance | Excellent |

| Packaging | Roll |

| Width | 1650mm, 2100mm, 2300mm, 2500mm, 3000mm |

| Moisture Barrier | Excellent |

| Heat Resistance | 160°F |

| Length | 250METERS |

| Surface | Smooth |

| Recyclable | No |

| Oxygen Barrier | Excellent |

| Material | Heat Sealing Film, Vacuum Bagging Film |

Applications:

Vacuum bagging film is mainly used for processing laminated glass. It is capable of handling a variety of complicated laminated glass designs, such as curved glass or embossed glass lamination, as well as DuPont SGP explosion-proof film lamination. This technology is highly efficient, easy to use, and requires comparatively low investment, with prices far lower than those of similar foreign products. Currently, companies such as CSG, AVIC Sanxin, Chuangyi Technology, Jiangmen Junfa Glass, Foshan Nanliang and Jiangsu Aolan all use this technology.

Support and Services:

At Vacuum Bagging Film, we are dedicated to providing our customers with superior technical support and services. We understand that a reliable product and excellent customer service are essential components of a successful business. That’s why we strive to provide the highest quality product and the best possible customer experience.

We offer a number of technical support services to our customers, including:

- Product selection assistance

- Installation and setup assistance

- Troubleshooting technical issues

- Technical advice and guidance

- Product and service updates

We also offer a variety of customer service services, such as:

- 24/7 customer support

- Dedicated customer service representatives

- Quick response times

- Technical training and education

- Product warranties

At Vacuum Bagging Film, we are committed to providing our customers with superior technical support and services. If you have any questions or need assistance with any of our products, please don’t hesitate to contact us.

Packing and Shipping:

Vacuum bagging film is usually supplied in two different formats: a roll or a sheet. The rolls are usually shrink-wrapped and boxed for shipping, while sheets are typically packed in bundles and shipped in boxes.

For rolls, we recommend that they be secured with shrink wrap and placed inside a box or pallet. The box should be large enough to accommodate the roll and provide some additional cushioning for protection during shipping. The shrink wrap should be secured tightly to the roll to ensure it does not shift during transit. If palletizing is necessary, the rolls should be stacked neatly on the pallet, with protective wrapping on the top and bottom of the stack.

For sheet packaging, we recommend that the sheets be bundled together and placed in a box. The box should be large enough to accommodate the bundle and provide additional cushioning for protection during shipping. It is also important to secure the bundle tightly within the box to prevent any shifting during shipping.

![]()