-

Glass Machinery Parts

-

Kevlar Aramid Ropes

-

Kevlar Sleeves Tube

-

Solid State Relay

-

Universal Caster

-

Heating Elements

-

Fused Silica Roller

-

Vacuum Bagging Film

-

Insulating glass machine accessories

-

Abrasive Tools

-

CNC Glass Cutting Machine

-

Glass Edging Machine

-

Glass Washing & Drying machine

-

Glass Tempering Machinery Accessories

-

Consumable Material

-

Transmission Belts

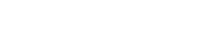

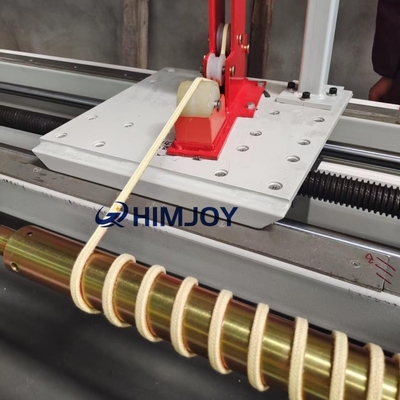

Aramid Ropes Winding machine equipment for roller table, kevlar rope wrapping machine

| Product Name | Kevlar Ropes Winding Machine | Application | Tempered Glass Machine Rollers |

|---|---|---|---|

| Material | Kevlar Aramid Fiber | Size | Customized |

| Specification | 12*3mm, 12*4mm, 5.5mm*5.5mm*250M Roll | Shape | Square/ Flat/ Round |

| Structure | Steel Frame Etc | Packing | Wooden Case |

| Feature | High Temperature Resistance |

Automatic Aramid Ropes wrapping machine, or called rope-winding machine.

Glass Tempering Furnace rollers use Aramid Ropes Winding machine equipment kevlar rope wrapping machine

Product Introduction:

Aramid ropes are wrapped on the rollers of the glass tempering furnace to facilitate the rapid transportation of high temperature glass. After the glass is heated in high temperature in the tempering furnace, it is cooled rapidly by the wind grid, and the Kevlar roller rope can effectively protect the high temperature glass from contacting the low temperature metal roller table without cold explosion and no scratch.

The Aramid ropes on the Glass tempering furnace quench rollers are used to protect the high temperature glass does not contact the low temperature metal roller conveyor without cold burst, no scratches, the existing roller conveyor rope is mostly through the rotation of the roller conveyor by rotating equipment, the roller conveyor rope manually winding on the roller conveyor, such a manual winding will lead to the space of roller conveyor rope is not uniform in each turn of the winding, and the rotation of the rotation equipment can not be smooth on the different lengths of roller conveyor rotation, but also lead to uneven space of the roller conveyor rope spacing is not uniform, so that the high temperature glass is easy to be deflected during the transportation process in the roller conveyor, leading to the glass to produce the fall, so we invent the roller ropes automatic wrapping machine, or called rope-winding machine.

Kevlar Rope Application:

Industrial use, clothing, high temperature, high strength, fire resistance, wear resistance, etc.

Kevlar Rope

Regular sizes:

| Flat Rope Size (Can be customized) | ||||

| Model | Width (mm) | Thickness (mm) | ||

| 8 x 3 | 8 | 3 | ||

| 8 x 4 | 8 | 4 | ||

| 10 x 3 | 10 | 3 | ||

| 10 x 4 | 10 | 4 | ||

| 10 x 5 | 10 | 5 | ||

| 12 x 3 | 12 | 3 | ||

| 12 x 3.5 | 12 | 3.5 | ||

| 12 x 4 | 12 | 4 | ||

| 12 x 4.5 | 12 | 4.5 | ||

| 12 x 5 | 12 | 5 | ||

| 12 x 5.5 | 12 | 5.5 | ||

| 13 x 2 | 13 | 2 | ||

| 13 x 3 | 13 | 3 | ||

| 13 x 3.5 | 13 | 3.5 |

||

| Square Rope Size (Can be customized) | ||

| Model | Width (mm) | Thickness (mm) |

| 4 x 4 | 4 | 4 |

| 5 x 5 | 5 | 5 |

| 5.5 x 5.5 | 5.5 | 5.5 |

| 6 x 6 | 6 | 6 |

| 8 x 8 | 8 | 8 |

| 10 x 10 | 10 | 10 |

| 12 x 12 | 12 | 12 |

| Round Rope Size (Can be customized) | ||

| Dia 2mm | Dia 3mm | Dia 4mm |

| Dia 5mm | Dia 6mm | Dia 8mm |

| Dia 10mm | Dia 12mm | Dia 20mm |

Size can be customized with special specifications

Detailed Photos:

![]()

![]()

Kevlar Rope Product Features:

- Woven with kevlar aramid fibers,

- Strong tensile strenght,

- Fire retardant,

- High temperature resistance 560℃,

- Wear resistance,

- Cut resistance,

- Corrosion resistance,

- High pressure resistant,

- High intensity,

- Abrasion resistant,

- Heat resistant,

- Chemical resistant,

- Electrical Insulator,

- Good mechanical property.

Kevlar Ropes Product Details:

If there is any problem with the quality, we are responsible for returning it!

![]()

Packing & Delivery:

MOQ, 1 piece = 1 roll (250meters),

we are professional manufacturer with many years experiences, self-produced direct sales, multi-specification, large-scale stock in stock, uninterrupted circulation supply!

We promise: 100% high-quality aramid yarn production, refusal to adulterate, cut corners, and serve our customers with quality and reputation.

![]()

![]()

FAQ:

1.Is your company a manufacturer or a trading company?

We are a manufacturer and have our own factory.

2.What is your lead time?

Generally it takes 30 days. The exact delivery time depends on the specific items and demanded quantity.

3.What terms does your company use in our international trade?

We usually do business in EXW works and door-to-door express . But if you have special requirement, we can also do in your convenience.