-

Glass Machinery Parts

-

Kevlar Aramid Ropes

-

Kevlar Sleeves Tube

-

Solid State Relay

-

Universal Caster

-

Heating Elements

-

Fused Silica Roller

-

Vacuum Bagging Film

-

Insulating glass machine accessories

-

Abrasive Tools

-

CNC Glass Cutting Machine

-

Glass Edging Machine

-

Glass Washing & Drying machine

-

Glass Tempering Machinery Accessories

-

Consumable Material

-

Transmission Belts

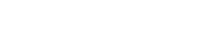

Convenient Easy Hand Glass Edges Grinding and Chamfering Machine

| Product Name | Convenient Glass Edge Grinding And Chamfering Machine | Application | Glass Edge Grinding |

|---|---|---|---|

| Max Glass Size Processed | 1800mm*2500mm | Voltage | 380V 50Hz |

| Machine Dimension | 2500mm*1500mm*1200mm | After-sales Service Provided | Field Maintenance And Repair Service |

| Weight | 400KGS | Power(w) | 3.1KW |

| Glass Thickness | 3~19m | Warranty | 1 Year |

| Product Name | Convecnient Glass Chamfering machine | |

|---|---|---|

| Max. Glass Size | 1800mm*2500mm | |

| Min. Glass Size | 150mm*150mm | |

| Feeding Glass Speed | 5~15m/min | |

| Overall size(L*W*H) | 2500mm*1500mm*1200mm | |

| Machine Power | 3.1KW | |

| Power Supply | 380V, 50Hz | |

| Machine weight | 400KGS |

Convenient Glass Edge Grinding and Chamfering Machine

1. Machine Application

The fast chamfering machine, a patented product developed by our company, is composed of a split structure for the main machine and worktable. It can be used for quick chamfering of tempered glass, insulating glass, door and window glass, etc.

2. Product features and working principle

- The workbench is equipped with water tank and electric control box.

- The independent main box body has unique advantages in structure. Different from the many drawbacks of traditional products.

2.1. The precise sealing structure of the wheel seat. It protects the bearing from damage caused by water.

2.2. Superior waterproof performance. The water circulation system does not affect the opening and closing of the cabinet, which facilitates the replacement of the grinding wheel and the future maintenance of the machine.

2.3. The drive system is reasonable and the life of the machine is extended. The exposed drive system well protects the power heart (motor) and various components.

Main features: convenient maintenance, ventilation and heat dissipation, moisture-proof, anti-corrosion of glass powder, etc.

3. Machine Main Features:

- Two grinding heads, the upper and lower wheels form an angle.

- With reference to the principle of four-side grinding, the rendering effect is better than that of four-side grinding, and the speed is better than that of four-side grinding. It has a buffer device + a film removing machine.

- The grinding wheel is a diamond wheel with 320 meshes, and the polished glass is smooth and delicate. It is calculated at eight hours a day. The life of the grinding wheel can be used for half a year (easy to change the grinding wheel)

- It can be connected to the film processor, and the height can be adjusted.

- The casing and water tank are made of stainless steel, and the water is recycled.

- Imported water-flush bearing can work continuously for eight hours without heating.

- Skilled workers work 600_800 square meters per day.

- Complicated specifications, no need to adjust, thickness adjustment is convenient, easy to use, can grind small plate 180*180, large plate 2m*2m, thickness range of 3~12mm glass.

- All electrical appliances are Chint (the lines are neat and easy to maintain).

- The appearance is electrostatic spraying (good corrosion resistance, high brightness, durable).

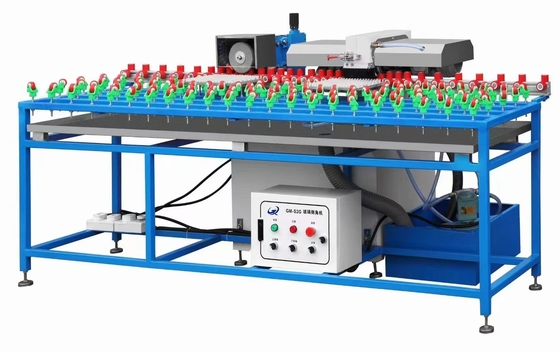

- Four movable working platforms (convenient to use large glass, height adjustment).

- The burst rate is almost 0.

- Save labor input cost, two people for four-side grinding (fixed and non-movable), and this type of edging only needs one person (less than one-tenth of its cost) (can be moved).

4. Technical Parameters:

| No. | Name | Parameters |

| 1 | Feeding speed: | 5~15m/min; |

| 2 | Min.glass size: | 150mm*150mm |

| 3 | Max.glass size: | 1800mm*2500mm; |

| 4 | Glass thickenss : | 3mm~12mm; |

| 5 | Power: | 3.1kw; |

| 6 | Overall size: | 2500mm*1500mm*1200mm ; |

| 7 | Machine weight | 400kg; |

![]()

![]()