-

Glass Machinery Parts

-

Kevlar Aramid Ropes

-

Kevlar Sleeves Tube

-

Solid State Relay

-

Universal Caster

-

Heating Elements

-

Fused Silica Roller

-

Vacuum Bagging Film

-

Insulating glass machine accessories

-

Abrasive Tools

-

CNC Glass Cutting Machine

-

Glass Edging Machine

-

Glass Washing & Drying machine

-

Glass Tempering Machinery Accessories

-

Consumable Material

-

Transmission Belts

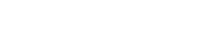

industrial Ceramic rollers for the glass tempering and processing kiln oven

| Product Name | Fused Silica Ceramic Rollers | Application | Glass Tempering Furnace Machine |

|---|---|---|---|

| Raw Material | Silica 99.8% | Bulk Density | >1.98 (g/cm3) |

| Apparent Porosity | 7-11 (%) | Compression Strength | ≥60 (MPa) |

| Diameter | 55mm, 60mm, 85mm, 95mm Etc | Surface Roughness | ≤1.5 (μm) |

| Packing | Fumigate Wooden Case | MOQ | 5 Pcs |

Industrial Ceramic rollers for the glass tempering and processing kiln oven

TamGlass Glasston Unic Landglass Northglass Mountain Glass Jinglass Tempering Furnace

![]()

Product Introduction:

The Fused Silica Ceramic roller, consisted of porcelain body, bearing, shaft and

plastic labyrinth sealing ring. Ceramic roller shaft is a key component in glass horizontal tempering furnace, mainly used for carrying and transporting glass in glass horizontal tempering furnace.

Application:

Glass Tempering Furnace, Silicon steel production, Lehr & lor float glass line, etc.

![]()

![]()

Basic Infomation:

| Raw Material | Silica | Bulk density | >1.98 (g/cm3) |

| Apparent porosity | 7-11 (%) | Press compression | 102 Mpa |

| Compression strength | ≥60 (MPa) | Expansion coefficient | 0.6*10-6/degree |

| Transverse strength | ≥30 (Mpa) | Certification | CE, RoHS |

| Expasion Coefficient | <0.6 (×10-6 /°C) | Warranty | 1 years |

| Surface Roughness | ≤1.5 (μm) | MOQ | 5 Pieces |

| OD Tolerance | ±0.05 (mm) | Density | 1.98g/cm3 |

| Radial Beat (Tolerance in rotation) | ≤0.10 (mm) | Package | Fumigate Wooden Case |

Size can be customized with special specifications

![]()

Sample drawing FYI

Detailed Photos:

![]()

![]()

![]()

Product Features:

High Purity.

High density.

Low porosity and critical manufacturing measurement.

The surface of the roller is smooth and delicate, the radial runout is small, the processing

accuracy is better than that of similar imported products, and it does not scratch the glass.

The steel head adopts anti-loose sleeve structure design and assembly, long service life.

The roll blank adopts the original grouting forming technology, which has the characteristics

of high density, high strength, no deformation at high temperature, wear resistance and long

service life.

High economic benefit, can reduce the comprehensive cost of belt conveyor, & reduce

maintenance man-hours.

Fused Silica Ceramic rollers which are mostly used in high grade Automobile, Electronic,

Solar etc glass manufacture.

Product Details:

If there is any problem with the quality, we are responsible for returning it!

Packing & Delivery:

MOQ, 5 pieces

we are professional manufacturer with many years experiences, self-produced direct sales, multi-specification, large-scale stock in stock, uninterrupted circulation supply!

We promise: 100% high-quality quartz production, refusal to adulterate, and serve our customers with quality and reputation.

![]()

![]()

Contact person:

Job Title : Sales Manager

Business Phone : +86 183 3883 9115

WhatsApp : +86 183 3883 9115

WeChat : +8618338839115

Email : sales@ycglassmachine.com